Galvanized is not a metal or alloy, it’s a process in which a protective zinc coating is applied to steel to prevent rusting. Due to its attractive price point and its corrosion resistance, galvanized wire mesh is very popular among industrial users of wire mesh. In the wire mesh industry, however, it is often treated as a separate category because of its wide spread use in all types of applications.

Jiushen galvanized is not a metal or alloy, it’s a process in which a protective zinc coating is applied to steel to prevent rusting. Due to its attractive price point and its corrosion resistance, galvanized wire mesh is very popular among industrial users of wire mesh. In the wire mesh industry, however, it is often treated as a separate category because of its wide spread use in all types of applications.

Galvanizing can occur either before or after wire mesh is manufactured - both in woven form or welded form. Galvanized before woven wire mesh or galvanized before welded wire mesh indicates the individual wires, themselves, used to manufacture the mesh have been galvanized before the mesh is woven or welded.

On the other hand, galvanized after is manufactured (normally in carbon or plain steel) and is often placed in a galvanizing tank, thereby making this a galvanized after woven or welded specification. Generally speaking, this option is more expensive, depending on availability and other variables, but does offer a higher level of corrosion resistance. This added level of corrosion resistance is most noticeable at the joint or intersection of galvanized after welded wire mesh specification. Keep in mind that galvanizing a relatively fine mesh, after it is woven, is likely to clog the openings rendering it unusable in numerous applications. It is for this reason that, usually, a 10 x 10 mesh and finer will be manufactured as a galvanized before woven item.

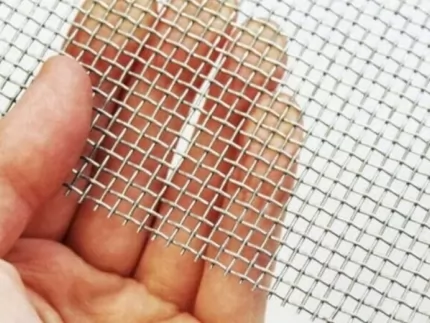

This type features a simple over-and-under weave pattern, creating a flat mesh with small, uniform openings.

It is known for its stability and is commonly used in filtration and sieving applications.

This construction type involves crimping the wires at their intersections, which adds extra strength and rigidity to the mesh.

The crimping process helps to lock the wires in place, making it suitable for applications requiring higher load-bearing capacity.

In welded wire mesh, the intersections of the wires are welded together, creating a strong and durable mesh.

This type is often used in construction for reinforcement purposes and in fencing applications.

Hexagonal wire mesh, also known as chicken wire, features a hexagonal pattern of woven and twisted wires.

It is lightweight, flexible, and commonly used in agriculture for animal enclosures and garden protection.

The galvanized wire mesh has a wide range of applications, including filtration and sifting, some of the items are also used as insect screening and similar applications.

Particle separation

Used in construction projects for fencing, caging, enclosures, and as infill panels.

Applied in high-security applications such as prison fencing and secure compounds.

Utilized for farm fencing, animal enclosures, and garden protection.

Employed in filtration and sifting processes, particle separation, and as a component in various industrial equipment.

Functions as window and safety guards, protecting against intruders and accidents.

Used in landscaping projects and as gabions for soil retention and erosion control.

Applied in archaeological excavations, greenhouse construction, and other specialized fields requiring durable and corrosion-resistant materials.

The zinc coating provides excellent protection against rust and corrosion, making it suitable for use in harsh environments.

The galvanizing process enhances the strength and durability of the wire mesh, ensuring it can withstand various environmental conditions.

The shiny, silver appearance of galvanized wire mesh gives it an attractive look, making it suitable for applications where appearance matters.

Despite the added cost of galvanizing, the extended lifespan and reduced maintenance costs make it a cost-effective solution in the long run.

| Material | Mesh Count | Wire Dia (mm) |

| Galvanized | 3 | 1.6 |

| Galvanized | 4 | 1.2 |

| Galvanized | 5 | 0.95 |

| Galvanized | 6 | 0.8 |

| Galvanized | 8 | 0.7 |

| Galvanized | 10 | 0.61 |

| Galvanized | 12 | 0.55 |

| Galvanized | 14 | 0.51 |

| Galvanized | 16 | 0.45 |

| Galvanized | 18 | 0.35 |

| Galvanized | 20 | 0.295 |

| Galvanized | 24 | 0.35 |

| Galvanized | 30 | 0.315 |

| Galvanized | 40 | 0.234 |

| Galvanized | 50 | 0.213 |

| Galvanized | 60 | 0.152 |

| Specific requirement can be customized by contact us | ||

How To Select The Suitable Epoxy Coated Wire Mesh For Filter Production

Epoxy Coating Peeling Off? - Epoxy Mesh Quality Problem Analysis And Preventive Measures

Epoxy Resin Coating Peeling Analysis

Mesh Deformation一Epoxy Coated Wire Mesh Quality Problem Corrective And Preventive Measures

Jiushen Self- Developed Super Epoxy Mesh Coating Line Was Fully Launched And Put Into Operation!

Jiushen Launched New Epoxy Coated Steel Wire Mesh For Hydraulic Filter Applications

Laboratory Effective Guarantee Of Product Quality

Jiushen Wire Weaving Aluminum Wire Manufacturer

Epoxy Coated 30# Aluminum Wire Mesh Is Available At Hebei Jiushen Wire Weaving Co., Ltd.

Comprehensive Upgrade of Aluminum Woven Wire Mesh for Air Filters

How Jiushen (JS) Innovates to Reduce Costs in Epoxy Coated Aluminum Screens Production

Galvanized Wire Mesh

Galvanized Wire Mesh

Copyright © Hebei Jiushen Wire Weaving Co., Ltd. All Rights Reserved. |

Sitemap

| Technical Support: