In this article we mainly discuss the corrective and preventive measures for epoxy mesh deformation.

For wire mesh weaving, if the wire tensile strength is high and the elongation is too small, the weaving is prone to serious uneven mesh holes.The solution is to select wires produced by large steel mills with CNC vacuum wire drawing and annealing process to make the material reach a soft state. For example,plain steel Q195 0.16mm wire, tensile strength 320-400MPa, elongation 18-25% is a good condition.

During warping process, no tension winding,uneven arrangement of the warp wire etc will cause mesh holes deformation in warp direction. The solution is to add tension wire spools and select non-damaged positioning steel buckle and width fixing buckle, and the warping equipment should be regularly maintained and lubricated strictly.

Weaving is the process that mesh deformation is most likely to occur. In short, if the warping process is normal and the weaving loom models and adjustment of this process are standardized, the only control changes are the mechanical properties of the weft wire and the adjustment and maintenance of the wire gripper. On the contrary, the mesh deformation will be caused by factors such as twisting time, heald frame height, coiling shaft pressure and parallelism, coiling shaft rubber surface wear, lubricant concentration etc. Therefore, standardization is the main direction to solve the problem. During the debugging process, observe in the direction parallel to the 45° direction of the mesh surface, and the grain shape will reflect the state of the mesh. Adjust the parameters in time until there is no problem with weaving.

Collision and extrusion during handling may cause mesh deformation. Solution: after weaving, the product shall be simply packed with kraft paper. Handling with care is the basic requirement. The contact surface of the handling tooling must be larger than the overall dimension of the product; Cancel the screen drawing inspection process and put it into storage directly (based on the complete control of mesh defects and deformation in the weaving process), and the stacking height is ≤ 3 layers.

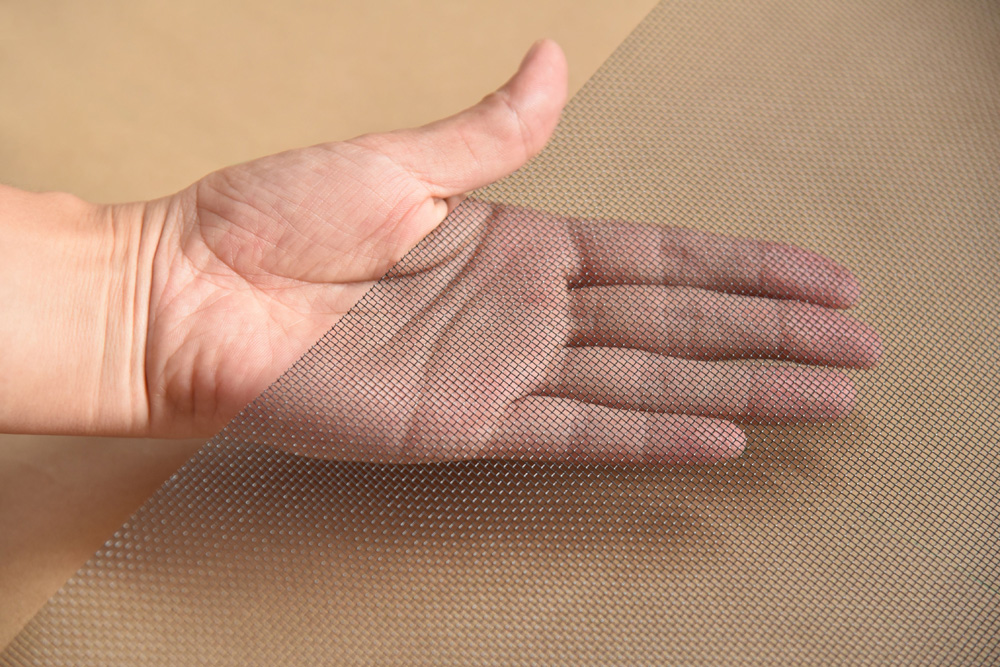

During the spraying process, the heat released during the melting and curing of the coating will cause the stress recovery of the wire. In addition, the self weight of the wire mesh in the curing furnace is uncontrollable. This force is very powerful in the micro level, which will cause the mesh surface to blister, and it is very easy to cause the overall deformation of the mesh surface. It is recommended to use longer coating lines, let the mesh rolls naturally opened during feeding. Through the double -wounding method, there will be more space for abnormal adjustments. This process has relatively high requirements for the accuracy and structure of coating equipment and personnel skills.

After years of practice, Jiushen Wire Weaving has established standard production mode, and the quality of our epoxy coated wire mesh is among the best in the industry. The maximum overall deformation of the weft wire in any weft direction of 20cm <5mm. Problems of bubbling, partial deformation (including S-type), collision and crush etc. all have been completely solved.

Copyright © Hebei Jiushen Wire Weaving Co., Ltd. All Rights Reserved. |

Sitemap

| Technical Support: