QUALITY CONTROL

ISO9001 Quality Management System

Jiushen operates the ISO9001:2015 quality management system, and relies on Anping provincial laboratory and factory testing equipment to effectively control product quality. In addition to strict requirements for supplier process quality control, Jiushen professional quality control department established a strict control and acceptance mechanism for materials, processes and delivery, and a traceability system for all products.

Raw Material Inspection Management

Raw materials are inspected according to ASTM A580/A580M-18, ASTM B95-96 and customer special requirements, using spectrometer/micrometer/universal tensile machine 100% inspection, marking each spool and save them by order.

Production Process Management

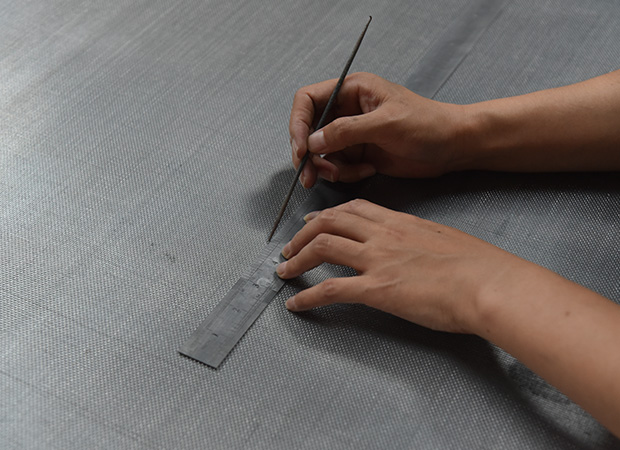

Weaving process is based on the corresponding order operation instructions, in conjunction with the testing methods and implementation standards, Jiushen established a three-level quality control responsibility system of employee self-inspection-monitor inspection-workshop supervisor inspection. Take equipment electronic error prevention measures, supplemented by equipment TPM Preserve, implement the TQM model, and adhere to the quality control of manufacturing process to achieve a pass rate of over 99% of finished products.

Finished Products Inspection Management

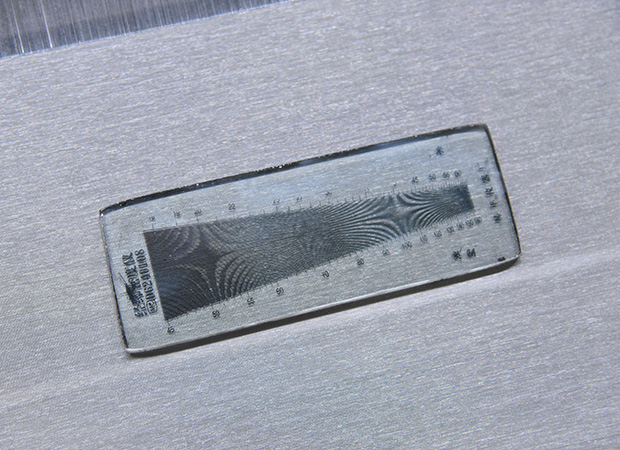

Finished product is subject to ASTM E2016-2020-5000, ASTM E2814-2011, GB/T 17492-2019 (ISO 9044-2016), GB 8380-1987, GB/T 21648-2008 and customer special requirements. Mesh count, width, length, mesh holes, mesh surface, coating and appearance are fully inspected; ultrasonic cleaning will be carried out when necessary. In accordance with the traceability coding rules, make processing and inspection records for each product and save them by order.

Traceability Management System

Traceability management system: Take order number as the main line, supplier code, product code, equipment code and serial number generate product traceability record codes, which are reflected in packaging labels according to customer needs. Create a file package for each order.

Testing instruments: spectrometer, micrometer, universal tensile machine, infrared carbon and sulfur analyzer, salt spray tester, anti-fatigue tester, impact tester, 200x optical magnifier, high temperature simulation box, spray booth etc.

Inspection

Hebei Jiushen Wire Weaving Co., Ltd.

Hebei Jiushen Wire Weaving Co., Ltd.

Hebei Jiushen Wire Weaving Co., Ltd.

Hebei Jiushen Wire Weaving Co., Ltd.

Hebei Jiushen Wire Weaving Co., Ltd.

Hebei Jiushen Wire Weaving Co., Ltd.

Hebei Jiushen Wire Weaving Co., Ltd.

Hebei Jiushen Wire Weaving Co., Ltd.

Quality Control for Epoxy Coated Wire Mesh

Copyright © Hebei Jiushen Wire Weaving Co., Ltd. All Rights Reserved. |

Sitemap

| Technical Support: