As an important component of hydraulic and air filter products, epoxy coated wire mesh is favored by major filter manufacturers all over the world. But for various specifications, which one is the most suitable for you? Based on our 20+ years of experience in this industry, a brief summary is provided for reference as follows.

The main function of the epoxy mesh is to play a supporting role, which can also be understood as the protection and impact resistance of the filter medias. It’s composed of substrate wire mesh + epoxy powder coating.

● The substrate mesh materials including Q195, Al5154, wire dia from 0.15mm to 0.3mm, mesh count from 8 mesh to 30 mesh, which can be customized according to the actual requirements of customers.

● The main components of epoxy resin coating are epoxy resin, filler, curing agent and pigment, which have certain influence on the mechanical properties and chemical properties of the metal mesh. The main function of the coating is the reinforcement and anti-corrosion effect of the solidified dense surface layer on the metal mesh.

Different mesh and powder combinations will produce different properties, such as: opening, thickness, weight, flexibility, color, corrosion and chemical resistance etc. It should be noted that the combination cannot exceed the range, for example: 30 mesh/0.30mm product, it’s opening size is about 0.54mm, if we want to make the coating thickness to be 0.54mm/2=0.27mm, it is obviously not possible. In addition, the particle size of the resin powder is between 35-45um, and the minimum thickness after curing and leveling is kept between 20-30um, so the minimum coating thickness is 20-30um. If you require a even thinner thickness less than 20um, the substrate wire mesh will be exposed.

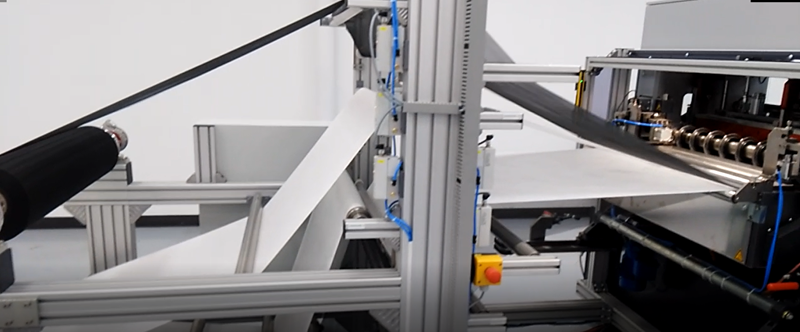

The processing process of most filter manufacturers is: cutting (or direct use) - pleating (together with filter paper) - truncation - edge sealing and pressing - end cap assembly - curing, but the equipment and processes used by each manufacturer may not all the same. In addition, even with the same equipment, there are differences in mechanical and chemical properties of epoxy coated meshes provided different suppliers.

A. Select epoxy mesh as per the application of the filters, air filters use Al5154 wire mesh +epoxy resin coating, hydraulic filters us Q195 steel wire mesh +epoxy resin coating.

B. According to the production process and performance requirements of the filters, blade-type high-speed pleaters produced by A2Z and JCEM are more suitable for wide-width epoxy mesh in order to improve production efficiency. The mesh surface should be flat, soft, and easy to pleat. The coating thickness should be about 25±4um, it is more appropriate to use matt or high-gloss epoxy resin powders with temperature and oil resistance of 150°C. The diameter of the metal wire is 0.15-0.18mm, which increases the filtering area of the pleated filters with the same diameter. For gear type pleaters, it is more suitable for epoxy mesh products with a wire diameter of 0.175-0.19mm and a coating thickness of 35±5um. High-gloss coatings with temperature resistance and oil resistance of 150°C are more suitable. The supporting force is strengthened, and the folding efficiency will be significantly improved; For products that require stronger support and damage resistance, Al 5154 30/0.30mm epoxy mesh products can be selected, and heavy-duty pleaters are required to improve the efficiency and quality, such as Rabofsky pleater.

C. Other types of filter processing technology, such as the end cap is plastic, belongs to hot-melt pressing, which is more suitable for the process of pleating while cutting to ensure that the width of the epoxy mesh and the width of the filter paper are consistent.

To sum up, considering the effective space of filter processing equipment, load capacity, usage scenarios etc. , Jiushen can develop epoxy mesh with different wire diameters, different mesh count, different coating properties, different packaging, different widths, different splicing methods, and different inner diameters of paper tubes.

Any problems you have with epoxy coated wire mesh, welcome to contact us. We are here to provide the correct solutions for you!

Copyright © Hebei Jiushen Wire Weaving Co., Ltd. All Rights Reserved. |

Sitemap

| Technical Support: