The uneven thickness of epoxy mesh coating mainly refers to that the thickness exceeds the normal tolerance, and there are also two extreme cases: missed spraying and mesh hole plugging.

Based on the principle of electrostatic spraying, the spray gun layout of the coating line and the characteristics of the wire mesh itself, the most common thickness excesses appears in the center and both sides of the wire mesh rolls. In addition to human factors, there are other reasons. Let’s introduce the reasons and solutions one by one as follows.

1. Uniform thick on both sides and thin in the middle: the root cause is the spray gun layout, and the Faraday effect. The solution is relatively simple: change the gun distribution structure from reciprocating to fixed. Spray from bottom to top instead of from top to bottom. The paint in the middle can be powdered twice to increase the thickness and reduce the mesh hole plugging. Choosing a flat nozzle spray gun will increase the irradiation area, make it more uniform, and reduce the long-term cost investment.

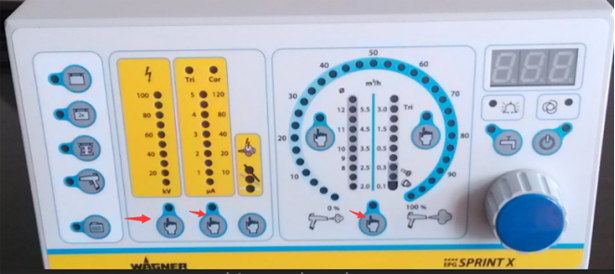

2. Partial thickness or thinness: it is mainly caused by the adjustment of spray gun parameters and the internal cleanliness of the gun body. Due to the existence of ultra-fine powder, excessive use of recycled powder will also cause thinness. In the control scheme, first use the recycled powder at the ratio of 15% to 20%, check the particle size of each batch of powder, and then regularly observe the powder output parameters of the spray gun.

3. Mesh Hole Plugging: in general, one plugging hole within 100m is allowed in the standard. Plugging a large area of holes will affect the filtering area and damage the filter paper, and directly affect the appearance (window screens are particularly important). The main reasons are that: there are sundries or lumps in the powder; the powder spraying system is not cleaned (including hardware facilities); and there are sundries on the wire mesh surface etc. The solution is that: the powder must be screened with 120 mesh screen before use, and the wire mesh must be cleaned before coating. Each shift (8h) of the spraying system must be cleaned with a compressed air gun. It is very necessary to maintain a clean working environment. The powder room and spray gun will accumulate a large amount of powder in the production process. With the increase of the epoxy powders, it will fall on the workpiece when it loses its adsorption force. In this case, usually a large-area of mesh hole plugging occurs. Once this happens, the epoxy mesh is scrapped.

4. Missed spraying: regardless any type substrate wire mesh, missed spraying must be eliminated and shall not occur. The reason for missing spraying is that the spray gun system is blocked (with sundries), there is a large amount of non-volatile grease or other substances on the screen surface, and the workpiece is scratched during powder spraying and curing. The first solution is to regularly clean and keep the spraying system clean and free of sundries, and the powder should be sieved before use. Secondly, the workpiece should be subject to high temperature or chemical degreasing to keep the surface clean. Another possible reason is that the spray gun voltage is insufficient or does not discharge, which cannot make the coating particles negatively charged and the workpiece is poorly grounded. In this case, the powder cannot adsorb with the workpiece, resulting in a large area of missed spraying.

More professional and detailed problems need to be analyzed and checked from the components of the spraying system, such as the wear of the powder pump, whether the powder pipe is worn, whether the high-pressure module is aging, whether the powder catching pipe is worn, whether the water content of the compressed gas meets the standard, etc.

It's recommended to use spray guns produced by Swiss GEMA, German WAGNER & and American Nordson. And use customized and developed epoxy powders provided by designated manufacturers.

Copyright © Hebei Jiushen Wire Weaving Co., Ltd. All Rights Reserved. |

Sitemap

| Technical Support: