Vietnam’s manufacturing sector has experienced rapid growth over the past decade, driven by foreign investment, favorable trade agreements, and the country’s strategic position in Southeast Asia. This expansion has led to increased demand for industrial equipment and materials that ensure efficiency, safety, and product quality. Among these, aluminium mesh filtration solutions have emerged as essential components across multiple manufacturing industries, from food processing and electronics to chemicals and metallurgy.

This article explores how Vietnam’s manufacturing boom is driving the adoption of aluminium mesh filtration systems, highlighting key applications, advantages, and considerations for selecting the right solutions for industrial operations.

Aluminium mesh filters provide a combination of strength, corrosion resistance, lightweight construction, and precise filtration, making them ideal for industrial applications.

Key Advantages of Aluminium Mesh Filtration:

1. Durability: Resistant to mechanical wear and pressure variations

2. Corrosion Resistance: Aluminium naturally resists rust, essential in humid or chemically active environments

3. Lightweight: Easy to install and replace, reducing operational downtime

4. Precision Filtration: Available in a wide range of mesh sizes for fine or coarse separation

5. Cost-Effective: Offers longevity and efficiency without high material costs

6. Eco-Friendly: Aluminium is recyclable, supporting sustainability initiatives

These benefits make aluminium mesh filtration solutions highly suitable for Vietnam’s rapidly modernizing factories, where both efficiency and regulatory compliance are critical.

Vietnam’s food processing industry is expanding rapidly, catering to domestic consumption and exports. Aluminium mesh filters are vital for:

1. Powder and Grain Separation: Sorting flour, sugar, rice, and spices for consistent product quality

2. Liquid Filtration: Removing pulp, sediments, or impurities from juices, sauces, and oils

3. Hygienic Processing: Aluminium mesh is easy to clean, meeting food safety standards

Impact: Ensures product quality, reduces contamination, and supports compliance with HACCP and ISO 22000 standards.

Vietnam is emerging as a hub for electronics manufacturing, with factories producing components, PCBs, and consumer electronics. Aluminium mesh filtration contributes by:

1. Air Filtration in Cleanrooms: Maintaining dust-free environments critical for high-precision components

2. Chemical and Liquid Filtration: Filtering process chemicals to prevent contamination in circuit boards and semiconductor materials

3. Equipment Protection: Prevents debris from entering sensitive machines

Impact: Enhances product reliability, reduces defect rates, and protects investment in precision machinery.

The chemical and pharmaceutical sectors require precise separation of solids, powders, and liquids. Aluminium mesh filters are applied in:

1. Powder Sieving: Ensuring consistent particle size in chemical compounds or drug formulations

2. Liquid Filtration: Removing impurities and contaminants in production lines

3. Protective Screening: Preventing foreign materials from entering reactors, mixers, or storage tanks

Impact: Improves product quality, enhances safety, and ensures regulatory compliance with GMP and other local standards.

Factories involved in metalworking, paint production, and heavy machinery require robust aluminium mesh filtration solutions to handle:

1. Metal Shavings and Particles: Screening and separating during cutting, grinding, and polishing operations

2. Dust Control: Maintaining cleaner workspaces in factories

3. Airflow and Cooling: Supporting ventilation and equipment cooling systems

Impact: Reduces equipment wear, improves operational efficiency, and enhances worker safety.

Manufacturers in Vietnam use a variety of aluminium mesh solutions depending on the application:

1. Sheet Mesh Panels: Used for large-scale sieving, screening, and protective guards

2. Roll Mesh: Flexible for custom cutting and retrofitting into existing machines

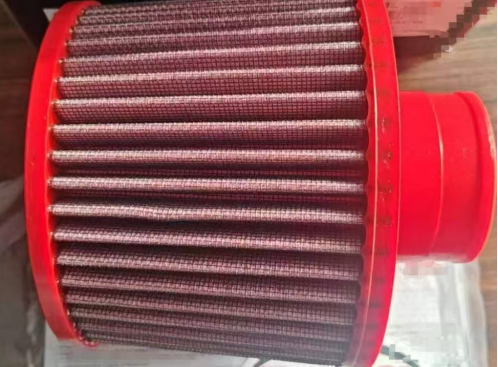

3. Tubular or Cylindrical Mesh Filters: Common in liquid filtration, chemical processing, and HVAC systems

4. Perforated Aluminium Mesh: Combines airflow and filtration in ventilation and drying systems

Considerations for selection: Mesh size, thickness, material treatment (anodized or coated), and compatibility with machinery.

Key Factors to Consider:

1. Mesh Size: Determines the precision of filtration; fine mesh for powders, coarse mesh for larger particles

2. Thickness: Stronger meshes for heavy-duty applications; thinner meshes for lightweight filtration

3. Corrosion Resistance: Anodized or coated aluminium extends service life in humid or chemical environments

4. Customizability: Roll, sheet, or cylindrical formats depending on application

5. Compliance: Meets food safety, chemical, or industrial standards as required

Tip: Partnering with a reliable supplier ensures proper sizing, quality assurance, and technical support.

1. Challenge 1: Corrosion in humid environments

2. Solution: Use anodized aluminium mesh or coated surfaces for enhanced resistance

3. Challenge 2: Clogging in powder or liquid processing

4. Solution: Select the correct mesh size and schedule regular cleaning or maintenance

5. Challenge 3: Mechanical stress in industrial operations

6. Solution: Choose thicker or reinforced aluminium mesh and secure it with supportive frames

7. Challenge 4: Custom application requirements

8. Solution: Work with manufacturers capable of producing mesh solutions in custom sizes, thicknesses, and formats

1. Automation Integration: Aluminium mesh is increasingly integrated into automated sorting, sieving, and filtration systems

2. Sustainability Focus: Recyclable aluminium aligns with environmental goals and regulations

3. Food and Beverage Expansion: Growing domestic and export demand is driving higher adoption of filtration solutions

4. Precision Manufacturing: Electronics and chemical industries increasingly rely on aluminium mesh for contamination control and equipment protection

Vietnam’s booming manufacturing sector has created a substantial demand for high-quality aluminium mesh filtration solutions. These filters provide durable, corrosion-resistant, lightweight, and precise filtration across food processing, electronics, chemicals, metallurgy, and industrial manufacturing.

Selecting the right aluminium mesh solution requires careful consideration of mesh size, thickness, material treatment, and application-specific requirements to ensure long-term efficiency, compliance, and safety.

For businesses looking for reliable aluminium mesh filtration solutions tailored to Vietnam’s diverse industrial needs, Jiushen offers a complete range of products designed for durability, precision, and performance, helping factories maintain high efficiency and product quality across all stages of production.

Copyright © Hebei Jiushen Wire Weaving Co., Ltd. All Rights Reserved. |

Sitemap

| Technical Support: