Aluminium mesh screens are versatile components widely used across various industrial and commercial sectors. Known for their durability, corrosion resistance, lightweight structure, and excellent filtration properties, these screens are integral in optimizing processes, improving safety, and enhancing efficiency. In Malaysia, where industries range from plantations and agriculture to manufacturing and food processing, aluminium mesh screens have become essential tools for both operational and environmental management.

This article provides a comprehensive overview of aluminium mesh screen applications in Malaysia, highlighting key industries, specific uses, and considerations for selecting the right mesh for your project.

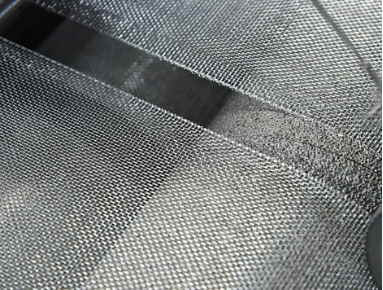

Aluminium mesh screens offer several advantages that make them preferable over other materials like stainless steel or nylon in certain applications:

1. Corrosion Resistance: Aluminium naturally resists rust and chemical damage, ideal for humid Malaysian climates

2. Lightweight and Durable: Easy to install, transport, and maintain while providing strong mechanical performance

3. Versatility: Available in multiple sizes, mesh counts, and thicknesses for filtration, screening, and protective purposes

4. Cost-Effective: Offers a balance of durability and affordability for large-scale industrial applications

5. Eco-Friendly: Aluminium is recyclable, supporting sustainability initiatives in industrial operations

Malaysia’s plantation sector, particularly palm oil, rubber, and cocoa, relies heavily on aluminium mesh screens for product quality control and processing efficiency.

Key Uses in Plantations:

1. Seed and Fruit Sorting: Separates seeds, nuts, and fruits by size for uniform processing

2. Debris Filtration: Prevents twigs, leaves, and foreign matter from entering machinery

3. Pulp and Oil Extraction: Facilitates proper separation of solids and liquids, improving extraction efficiency

4. Drying and Ventilation: Supports airflow while retaining product quality

Benefits:

1. Prevents machinery damage from debris

2. Enhances product consistency and quality

3. Reduces maintenance downtime

Aluminium mesh screens are crucial in food processing plants, where hygiene, product quality, and safety are top priorities.

Key Uses in Food Processing:

1. Sieving and Grading: Sort powders, grains, nuts, or other food products according to size

2. Filtering Liquids: Removes pulp or solids in juice, oil, or sauce production

3. Drying and Cooling: Ensures even airflow in ovens or cooling chambers

4. Safety Guards: Protects operators and prevents contaminants from entering production lines

Benefits:

1. Improves food quality and safety compliance

2. Reduces product wastage

3. Ensures smooth operation of machinery

Aluminium mesh screens are widely adopted in industrial factories in Malaysia, including electronics, chemical processing, and construction material production.

Key Uses in Factories:

1. Filtration: Filters air, water, or chemicals, preventing contamination

2. Protective Guards: Protects workers from moving machinery or hot surfaces

3. Material Separation: Separates powders, granules, or metal shavings

4. Ventilation and Cooling: Maintains airflow in equipment housings, reducing overheating risks

Benefits:

1. Reduces operational risk and improves worker safety

2. Supports efficient production workflows

3. Minimizes contamination in sensitive processes

Beyond industrial uses, aluminium mesh screens also find applications in construction and architecture.

Key Uses in Construction:

1. Facades and Sunshades: Lightweight mesh provides ventilation and sunlight control

2. Insect Screens: Protects indoor spaces from pests while allowing airflow

3. Filtration in HVAC Systems: Filters dust and debris from ventilation ducts

4. Safety Barriers: Used in fencing, balcony railings, or machine guards

Benefits:

1. Long-lasting, corrosion-resistant solution

2. Enhances building ventilation and aesthetics

3. Reduces maintenance costs compared to alternative materials

Choosing the correct aluminium mesh screen depends on application, mesh size, thickness, and environmental factors.

Key Considerations:

1. Mesh Size: Finer meshes for powders, coarser for larger solids

2. Thickness: Stronger meshes withstand higher mechanical stress; thinner meshes suitable for lightweight filtration

3. Coating or Anodizing: Improves corrosion resistance in humid or chemical environments

4. Installation Requirements: Panels, rolls, or custom-cut sizes depending on machinery or structural needs

5. Compliance: Ensure mesh screens meet industry-specific hygiene and safety standards

1. Challenge 1: Corrosion in humid plantation areas

2. Solution: Use anodized or coated aluminium mesh for extended lifespan

3. Challenge 2: Mesh clogging in food processing

4. Solution: Implement regular cleaning and select appropriate mesh size

5. Challenge 3: Mechanical damage in industrial factories

6. Solution: Choose thicker or reinforced mesh screens; use protective frames

7. Challenge 4: Sourcing customized mesh for specialized applications

8. Solution: Partner with reliable manufacturers capable of producing custom mesh sizes, thicknesses, and panels

1. Sustainable Manufacturing: Aluminium mesh is increasingly preferred due to recyclability and lightweight properties

2. Automation Integration: Mesh screens are integrated into automated sorting, drying, and filtration systems

3. Hygiene Standards: High-quality mesh ensures compliance with local and international food safety regulations

4. Urban and Architectural Expansion: Widely adopted in construction for facades, sunshades, and ventilation applications

From plantations and food processing to factories and construction, aluminium mesh screens play a pivotal role in Malaysia’s key industries, enhancing operational efficiency, product quality, and safety. Selecting the right mesh involves considering mesh size, thickness, material treatment, and application-specific requirements to ensure durability and performance.

For businesses seeking high-quality aluminium mesh screens suitable for plantations, food processing, industrial, and construction applications, Jiushen provides a comprehensive range of products designed for precision, durability, and long-term performance, helping Malaysian industries achieve efficiency and excellence at every stage of their operations.

Copyright © Hebei Jiushen Wire Weaving Co., Ltd. All Rights Reserved. |

Sitemap

| Technical Support: