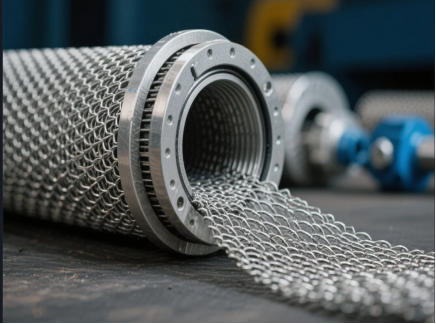

When it comes to maintaining hydraulic systems, contamination control is everything. Tiny particles invisible to the naked eye can cause catastrophic failures in pumps, valves, and actuators. That’s why hydraulic filter elements are vital in keeping oil clean and systems running efficiently. At the heart of those elements lies one crucial component — the filter mesh.

Choosing the correct mesh size can make the difference between uninterrupted productivity and expensive downtime. This guide will help engineers, maintenance managers, and procurement professionals understand the key factors in selecting the right mesh size for hydraulic filter elements — whether for mobile machinery, industrial plants, or OEM system manufacturing.

Mesh size refers to the number of openings per inch in a filter screen or mesh. For example, a 100-mesh screen has 100 openings per linear inch. However, this is just one part of the equation. More accurate filtration performance is expressed in microns (µm), which measure the actual size of the particles the mesh can trap.

Mesh Size | Approx. Micron Rating |

10 mesh | ~2000 µm |

60 mesh | ~250 µm |

100 mesh | ~150 µm |

200 mesh | ~75 µm |

400 mesh | ~37 µm |

Important: Mesh count alone does not reflect filtration performance. Factors like wire diameter, weave type, and material also play a role in real-world efficiency.

In hydraulic systems, fluid cleanliness level (FCL) directly correlates with equipment life. Research has shown that up to 70–90% of hydraulic failures can be traced back to fluid contamination. Choosing the wrong mesh size can lead to:

· Undetected particle ingress, causing wear and tear

· Premature filter clogging, reducing flow and increasing pressure drop

· Pump cavitation or system starvation, damaging components

· Increased maintenance costs and reduced uptime

Selecting the optimal mesh size is a critical design decision, especially in high-pressure, high-performance environments such as excavators, presses, CNC machinery, and automated systems.

Let’s break down the main criteria to consider when specifying mesh size for hydraulic filter elements:

Start by analyzing the typical contaminants found in your hydraulic fluid. This can include:

· Metal wear particles from pumps and valves

· Dust or sand in mobile applications

· Seal debris and rubber fragments

· Water droplets or emulsions

· Oxidation sludge in high-temperature systems

If your fluid analysis shows particles as small as 20 µm causing wear, your mesh should filter at or below this threshold. Use tools like ISO 4406 cleanliness codes to guide your selection.

Higher flow systems require less restrictive meshes to avoid pressure drop. On the other hand, slow-flow systems (like in lube return lines) can handle finer mesh sizes without choking the system.

· For high-pressure lines (>200 bar): Select meshes with a balance of strength and low pressure drop

· For return lines or reservoirs: You can afford finer filtration for better fluid cleanliness

· Always evaluate the pressure drop vs. flow curve for your chosen mesh material

Pro tip: A 10–15 psi pressure drop across the filter is acceptable in most hydraulic systems. Anything above may require a redesign.

The ideal mesh size also depends on where the filter is installed:

· Suction Filters: Coarser mesh (e.g., 100–150 µm) to prevent pump starvation

· Pressure Line Filters: Medium to fine mesh (e.g., 10–40 µm) to protect sensitive components

· Return Line Filters: Finer mesh (e.g., 5–25 µm) to remove particles before oil re-enters the reservoir

· Offline or Bypass Filters: Very fine mesh (e.g., 3–10 µm), since flow can be slowed down for deep filtration

Hydraulic systems with tight tolerances, like servo valves or proportional valves, demand cleaner oil. In such cases, consider a multi-layer mesh or integrated media that captures particles below 10 microns consistently.

If the system is relatively robust — for instance, agricultural or construction equipment — a larger mesh size may be sufficient for primary filtration.

Fine mesh must withstand fluid pressure, vibration, thermal cycles, and chemical exposure. The right mesh size won’t matter if the mesh itself deforms or corrodes.

Common mesh materials include:

· Stainless Steel 316L – corrosion-resistant and widely used

· Bronze/Brass – suitable for non-aggressive fluids

· Monel or Hastelloy – high-strength alloys for extreme environments

· Sintered Mesh Laminates – layered structures that increase strength without sacrificing micron rating

Make sure the mesh can hold shape under pressure and is compatible with your fluid type (especially synthetic or fire-resistant fluids).

Mesh filters can often be cleaned and reused — but only if sized and structured properly. If you plan for backwashing, ultrasonic cleaning, or manual rinsing, choose:

· Sturdier mesh weave (like twill or sintered)

· Accessible mesh elements that are easy to remove and clean

· Micron ratings that don't clog prematurely under normal operating loads

Ensure your chosen mesh meets relevant filtration standards, such as:

· ISO 16889: For multi-pass filter efficiency testing

· ISO 4406: For fluid cleanliness codes

· DIN/ASTM mesh specifications: For dimensional accuracy

Also, verify that your supplier provides certification documents, lot traceability, and material test reports (MTRs) for quality assurance.

If you’re building or maintaining custom hydraulic equipment, you may need non-standard mesh sizes, shapes, or mounting styles. In that case, work with a supplier who offers:

· Custom cutting, shaping, and welding

· Pleated or layered mesh construction

· Integration into conical, cylindrical, or disc elements

· OEM packaging or labeling

Tailored mesh solutions ensure seamless integration and performance consistency across large production volumes.

Even experienced buyers can fall into these traps:

· Choosing too fine a mesh and causing flow restriction

· Overlooking mesh weave type, which affects actual opening size

· Forgetting to match mesh strength to pressure and vibration levels

· Assuming micron = mesh count (they are not equivalent!)

· Selecting non-compatible materials that corrode over time

Avoiding these mistakes can extend both filter and system life.

Many suppliers offer:

· Micron vs. mesh conversion charts

· Pressure drop calculators

· Contamination level calculators

· Fluid compatibility guides

Using these tools during procurement or system design can streamline the mesh selection process.

Choosing the correct mesh size for your hydraulic filter elements is more than just picking a number — it’s a system-critical decision that influences fluid cleanliness, equipment lifespan, and operating efficiency. Whether you're sourcing filters for a mobile excavator or designing an industrial press, your mesh selection must balance filtration efficiency, flow performance, material durability, and system tolerance.

Use this guide to make informed decisions and avoid costly errors that can undermine your entire hydraulic system.

Jiushen offers a wide range of custom-engineered mesh solutions for hydraulic filter elements. Whether you need high-micron stainless steel mesh, multi-layer sintered screens, or OEM-ready designs, we help you strike the perfect balance between filtration performance and flow efficiency.

Precision starts with the right mesh.

Contact Jiushen today for expert recommendations and fast, reliable supply.

Copyright © Hebei Jiushen Wire Weaving Co., Ltd. All Rights Reserved. |

Sitemap

| Technical Support: