You can get hurt if you work near machines without guards. Many workers each year get injuries like crushed hands, amputations, burns, or blindness because they are not protected.

Type of Injury | Annual Incidents |

Crushed fingers or hands | Thousands |

Amputations | Thousands |

Burns | Thousands |

Blindness | Thousands |

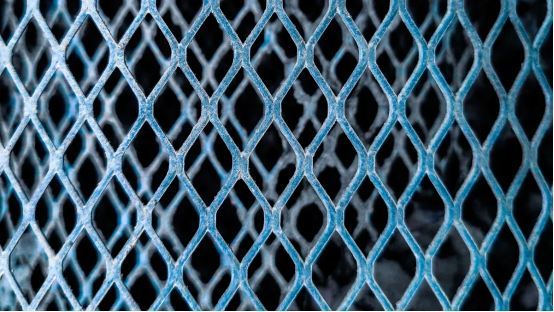

Aluminum Alloy Mesh is a new way to guard machines. This material keeps you safe from moving parts and flying pieces. It also protects you from getting pinched. You can still see through it clearly. It does not rust and works well in hard places. You can trust it because it meets ANSI and OSHA rules. These rules say machines must have strong guards. Aluminum Alloy Mesh gives you safety, lasts a long time, and is easy to use at work.

· Aluminum alloy mesh gives strong protection from machine dangers. It helps stop injuries like crushed hands and burns. This mesh lets workers see machines clearly. Workers can spot problems early. This helps keep the workplace safe. Aluminum alloy mesh lasts a long time and does not rust. It is a good choice for many factories. Using aluminum mesh can save time and money on repairs. It is better than using plastic or wood. Aluminum alloy mesh is flexible. It can fit many machines and change for new safety needs.

Machine guarding helps keep people safe from dangerous machine parts. Guards stop your hands, arms, or body from touching moving parts or sparks. They also block flying debris. There are different guards for different machines and jobs. Here is a table that lists common guards and what they do:

Type of Guarding | Description | Purpose |

Fixed Guards | Barriers that stay in place all the time | Very strong and need little care |

Interlocked Guards | Turn off machines if you open them | Great for fixing or cleaning machines |

Adjustable Guards | Can be moved to fit different jobs or materials | Good for places that change tasks often |

Self-Adjusting Guards | Change shape to fit different material sizes | Best when you make many different things |

Presence-Sensing Devices | Use sensors to see if someone is too close | Stop machines if a person gets near danger |

Two-Hand Controls | Make you use both hands to start the machine | Keep hands away from dangerous spots |

You must follow safety rules from OSHA and ANSI for machine guarding. These rules are:

· OSHA 29 CFR 1910.212 – General Machine Guarding

· OSHA 29 CFR 1910.147 – Lockout/Tagout

· ANSI B11 Series – Machine-specific safety

· ISO 13849 / IEC 62061 – Functional safety

Aluminum alloy mesh is a new way to help keep machines safe. You see this mesh in fences, panels, and covers around machines. The mesh lets you look at the machine but keeps you safe. It also lets air move through, so machines stay cool.

You find aluminium alloy mesh in guards made with strong 6000 series aluminum. These guards often use T-slotted frames, so you can build guards for any machine. The mesh is simple to cut and shape, so it fits many machines. Some guards use colors, like red for danger and silver-white for warning. Safety parts like interlocking devices and alarm switches can connect to the mesh. If you open a safety gate, the machine can turn off right away.

New designs use frames you can take apart and put back together. You can change them as your needs change. This makes aluminum alloy mesh a smart and flexible choice for many jobs.

Aluminum alloy mesh gives you strong safety when you work near machines. You need safety solutions that stop accidents and keep you away from dangerous parts. This mesh blocks your hands and body from moving gears, belts, or blades. You stay safe because the mesh acts as a barrier. You see the machine clearly, so you know when something is wrong. You also get good airflow, which helps machines work better and keeps the area cool.

You want safety solutions that last a long time. Aluminum alloy mesh stands up to hard hits and rough use. It does not break or bend easily. You can use it in places with heavy machines or lots of movement. The mesh keeps its shape and protects you every day. Other materials like plastic or wood wear out fast. You need to fix or replace them often. Aluminum alloy mesh stays strong and needs less care.

· Aluminum alloy mesh resists corrosion and keeps working for years.

· Plastic and wood guards break down and need more repairs.

· Metal mesh, like aluminum or stainless steel, handles tough weather and heavy use.

You save time and money because you do not need to fix the mesh often. You get safety that lasts.

You need to see machines to check for problems. Aluminum alloy mesh lets you watch moving parts without getting close. You spot trouble early and avoid accidents. The mesh does not block your view, so you work with confidence. Good visibility is a key part of safety.

· Wire mesh lets you see machines and moving parts.

· You get clear views, which helps prevent accidents.

· The mesh allows air to flow, so machines do not overheat.

You work in a safer place because you see what is happening. You also get fresh air, which makes the area more comfortable.

Tip: Always check the mesh for damage. Good visibility helps you spot problems fast.

You need safety solutions that work in wet or harsh places. Aluminium alloy mesh does not rust. You use it outdoors or in places with chemicals. The mesh keeps you safe even when the air is damp or dirty. Steel can rust and plastic can crack, but aluminum alloy mesh stays strong.

1. Aluminum mesh has a natural coating that stops rust.

2. You use it in places with water, chemicals, or outdoor weather.

3. The mesh keeps its safety features for a long time.

You get safety that does not fade, even in tough conditions.

Material | Durability | Corrosion Resistance | Maintenance Needs | Safety Solutions |

Aluminum | High | Excellent | Low | Long-lasting |

Steel | High | Good (can rust) | Medium | Strong |

Plastic | Low | Poor | High | Short-term |

Wood | Low | Poor | High | Short-term |

Aluminum alloy mesh gives you safety solutions that protect you, last longer, and work in many places. You get safety every day, with less worry about repairs or damage.

You need to know what makes each material different. Aluminium alloy mesh is strong, lasts long, and bends easily. Steel guards are strong too, but they can rust and are heavy. Plastic guards are light and easy to shape, but they break fast and are not as safe.

Material | Safety Level | Durability | Flexibility | Weight | Corrosion Resistance |

Aluminum Mesh | High | High | High | Light | Excellent |

Steel | High | High | Medium | Heavy | Good |

Plastic | Medium | Low | High | Very Light | Poor |

Aluminum mesh lets you see machines better than steel or plastic. You get more air flow, so machines stay cool. You can spot problems early. Aluminum mesh follows safety rules. You can use it in wet or chemical places because it does not rust.

Note: All guards must be tight and have no sharp edges. This keeps them safe for everyone.

You want a guard that saves money over time. Aluminum alloy mesh is cheaper to care for than steel or plastic. You clean it gently with safe cleaners. If you work near the ocean, clean the mesh more often to stop salt from building up. Check the mesh every few months to find small problems before they get worse.

· You can buy guards that you change or add to easily. You can add fire-proofing or dust-proofing. You can connect the mesh to machine controls.

· You can shape aluminum mesh to fit any machine, even odd shapes.

· Good help and support make your safety system work better.

When you choose a guard, think about dangers at work, your machine design, and how easy it is to get help. Aluminum alloy mesh gives you safety for a long time. It is strong and can change as you need.

Aluminum alloy mesh is used in many factories. It helps protect people from moving machines. Wire mesh safety guards build fences around robots and presses. These guards stop you from touching dangerous parts. You can see machines clearly through the mesh. This helps you check for problems. Industrial wire mesh works for perimeter guards and safety barriers. You can shape the mesh to fit any machine. It works in small workshops and big factories.

Application Type | Description |

Aluminum Machine & Perimeter Guards | Lightweight aluminum profiles make guards for many places. They help keep work safe and organized. |

Custom Designed Perimeter Safety Fencing | Aluminum fences are made for safety and security jobs. |

Food and drug plants need high safety. Aluminum alloy mesh does not rust, so it keeps areas clean. Industrial wire mesh makes fences around mixers and packaging lines. The mesh lets air move and keeps machines cool. Wire mesh safety guards build barriers to stop you from getting too close. These barriers help you follow safety rules. They also keep products safe from contamination.

Application Type | Description |

Fence Enclosures | Wire mesh is used to make safe enclosures for many jobs. |

Some machines need special protection. Industrial wire mesh gives flexible fences and barriers. You can design barriers for odd shapes or tight spaces. Safety barrier materials build panel enclosures that fit your needs. Many companies pick aluminum alloy mesh for custom jobs. It is light, strong, and easy to shape. You can add locks, sensors, or alarms for extra safety.

Note: Custom solutions can be tricky. Raw material prices can change costs. Some jobs use steel mesh, so compare options. Custom designs need skilled workers to install.

· Raw material prices can change

· Steel and stainless steel mesh compete

· Skilled workers needed for hard installs

Industrial wire mesh gives strong protection and long-lasting safety. It offers flexible fences for many industries. Safety barrier systems work in tough places and keep you safe every day.

Aluminum alloy mesh helps keep you safe near machines. It meets safety rules and makes your workplace safer. You can see machines easily and air moves through the mesh. Many industries use mesh and change it to fit their needs. People pick aluminum alloy mesh for safety and because it lasts a long time. You should think about using mesh guards for your next project.

Mesh is a grid made from metal wires. You use mesh to build barriers around machines. Mesh keeps you safe by stopping you from touching moving parts. You see through mesh and check machines easily.

Wire mesh protects you in industrial places. You use wire mesh to block dangerous machine parts. Wire mesh lets you see machines and keeps air moving. Wire mesh helps you follow safety rules.

You find mesh guards on presses, robots, and conveyors. Industrial machines need mesh guards to keep workers safe. Wire mesh fits many shapes and sizes. You use mesh in factories, workshops, and plants.

Aluminum alloy mesh lasts longer than other wire mesh. You get strong protection and less rust. Aluminum mesh is light and easy to shape. You use aluminum mesh in wet or harsh industrial places.

You look for broken wires or loose mesh. You check mesh for sharp edges. You make sure mesh is tight and covers all dangerous spots. You inspect mesh often in industrial areas.

Copyright © Hebei Jiushen Wire Weaving Co., Ltd. All Rights Reserved. |

Sitemap

| Technical Support: