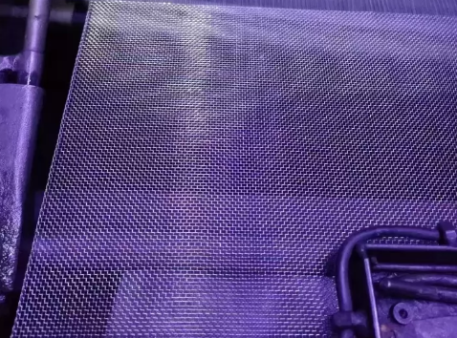

The global construction and infrastructure sectors are experiencing unprecedented growth due to rapid urbanization, industrialization, and the need for sustainable and resilient structures. Among the materials that have gained significant attention in recent years, aluminum alloy wire mesh stands out for its versatility, strength, and corrosion resistance. From building facades and safety barriers to industrial filtration systems, aluminum alloy wire mesh is increasingly becoming a key component in large-scale infrastructure projects worldwide.

As governments invest heavily in transportation networks, urban redevelopment, and industrial expansions, the demand for high-quality, durable, and lightweight materials has soared. Aluminum alloy wire mesh, with its unique combination of physical properties and adaptability, has emerged as a preferred solution for architects, engineers, and procurement professionals aiming to meet both functional and aesthetic requirements.

Urbanization continues to be a major driver of infrastructure demand. Cities across Asia, Europe, and North America are expanding their transport, residential, and commercial facilities. In these projects, aluminum alloy wire mesh plays a crucial role in:

Building Facades: Offering lightweight yet durable cladding solutions for skyscrapers and commercial complexes. Its corrosion resistance ensures longevity in varying climatic conditions.

Sunshades and Ventilation Panels: Providing aesthetic designs while allowing air circulation and reducing solar heat gain.

Public Spaces: Enhancing safety and design in parks, pedestrian walkways, and urban squares.

In smart city projects, where sustainability and energy efficiency are prioritized, aluminum alloy wire mesh is increasingly being used in green building applications, including solar panel protection screens and airflow optimization systems.

Modern transportation projects demand materials that can withstand high stress while being lightweight to reduce structural load. Aluminum alloy wire mesh is widely used in:

Bridges and Railways: Serving as guardrails, fencing, and walkway coverings that meet both safety and regulatory standards.

Highway Noise Barriers: Acting as durable panels that can reduce sound pollution while resisting weathering.

Airport and Subway Facilities: Providing security fencing, partitioning, and maintenance access panels.

The material’s high tensile strength and corrosion resistance make it suitable for coastal and harsh weather environments, where steel may deteriorate more rapidly.

The industrial sector, including power plants, chemical factories, and oil & gas facilities, has seen a growing reliance on aluminum alloy wire mesh due to its chemical resistance and long service life. Applications include:

Filtration Systems: Mesh screens in cooling towers, chemical reactors, and air filtration systems.

Protective Enclosures: Safeguarding machinery while allowing visibility and ventilation.

Cable Management and Conduits: Lightweight, corrosion-resistant solutions for organizing and protecting electrical and mechanical systems.

In renewable energy projects, especially solar and wind installations, aluminum alloy wire mesh is increasingly used in protective barriers and module frames, enhancing both efficiency and durability.

Modern production technologies, including precision weaving, perforation, and anodizing, have enhanced the performance and aesthetic versatility of aluminum alloy wire mesh. These innovations allow for custom mesh sizes, patterns, and finishes, meeting specific project requirements in architectural, industrial, and urban applications.

Governments and international bodies enforce stringent standards for construction materials. Aluminum alloy wire mesh often meets ISO, ASTM, and EN standards, ensuring compliance in critical infrastructure projects. Its fire-resistant, corrosion-resistant, and non-toxic properties make it a reliable choice for both public and private sector developments.

Aluminum is 100% recyclable without losing its mechanical properties, making aluminum alloy wire mesh a sustainable material choice. As the construction industry increasingly adopts green building practices, the demand for recyclable, energy-efficient, and low-maintenance materials is expected to rise.

While initial costs may be slightly higher than standard steel mesh, the long-term durability and minimal maintenance requirements of aluminum alloy wire mesh provide significant savings over the lifecycle of a project. Reduced risk of corrosion, low weight, and ease of installation also contribute to cost efficiency, particularly in large-scale infrastructure projects.

The Asia-Pacific region, led by China, India, and Southeast Asian countries, represents the largest market for aluminum alloy wire mesh. Massive urbanization, high-speed rail networks, and industrial expansions are driving demand. The adoption of advanced manufacturing techniques in these regions further supports the growth trajectory.

Europe emphasizes architectural innovation and sustainability. Aluminum alloy wire mesh is favored in modern building facades, public art installations, and heritage restoration projects. Countries like Germany, France, and the UK are witnessing steady growth due to stringent building codes and environmental regulations.

In North America, infrastructure modernization initiatives, including bridge rehabilitation, airport expansions, and commercial construction projects, are increasing the demand for aluminum alloy wire mesh. Lightweight and durable materials are crucial to comply with seismic and wind load requirements.

Mega-projects in the Middle East, including airports, stadiums, and industrial parks, leverage aluminum alloy wire mesh for decorative facades, security fencing, and industrial applications. Africa’s emerging infrastructure sector, especially in power generation and transport, also contributes to market expansion.

Architectural and Decorative Use: Modern commercial and residential buildings increasingly utilize aluminum alloy wire mesh for interior and exterior aesthetics, providing innovative textures, transparency, and pattern designs.

Safety and Security: Airports, stadiums, and urban transportation hubs adopt aluminum alloy wire mesh for fencing, barriers, and protective panels, meeting rigorous safety standards.

Filtration and Industrial Use: Industrial facilities leverage the corrosion resistance and customizable apertures of aluminum mesh in filtration, separation, and machine protection applications.

Agricultural and Environmental Applications: Mesh is widely used in greenhouses, solar farms, and water treatment plants, offering protection and durability while supporting sustainable operations.

Despite its advantages, the aluminum alloy wire mesh market faces certain challenges:

Raw Material Price Volatility: Fluctuating aluminum prices can impact project budgets.

Competition from Steel and Stainless Steel Mesh: While aluminum offers unique properties, some applications still favor traditional steel.

Technical Expertise Required: Advanced installation techniques and custom designs demand skilled labor, which can limit adoption in some regions.

However, the overall demand remains robust due to increasing infrastructure spending, urban development initiatives, and preference for sustainable materials.

The aluminum alloy wire mesh market is expected to grow steadily over the next decade, driven by global infrastructure projects, innovative architectural applications, and industrial expansions. Key trends include:

Expansion in customized mesh patterns and sizes for aesthetic and functional requirements.

Increased use in renewable energy and green building projects.

Adoption of automated and precision manufacturing processes to meet high-volume infrastructure demands.

Growth in emerging markets with high infrastructure investment potential.

With the rising focus on sustainability, durability, and design flexibility, aluminum alloy wire mesh will continue to be an integral component of modern construction and industrial projects worldwide.

As urbanization, industrialization, and infrastructure modernization accelerate globally, the demand for versatile, durable, and lightweight materials like aluminum alloy wire mesh is set to rise. Its wide-ranging applications—from architectural facades and industrial filtration to safety barriers and renewable energy projects—underscore its essential role in modern infrastructure development. Stakeholders in construction, industrial, and energy sectors increasingly recognize aluminum alloy wire mesh as a cost-effective, sustainable, and high-performance solution for complex engineering challenges.

For top-quality aluminum alloy wire mesh solutions tailored to your infrastructure needs, Jiushen offers unparalleled expertise, premium products, and reliable global supply, ensuring your projects achieve both efficiency and longevity.

Copyright © Hebei Jiushen Wire Weaving Co., Ltd. All Rights Reserved. |

Sitemap

| Technical Support: