When specifying aluminum screen mesh for windows, doors, patios, or large-scale building projects, the frame material is just as critical as the mesh itself. While the mesh provides insect protection and ventilation, the frame ensures structural integrity, long-term durability, and visual harmony.

A mismatched or poorly chosen frame can compromise the entire system—leading to warping, corrosion, sagging mesh, or premature failure. These issues not only increase maintenance costs but can also disrupt building operations and reduce occupant comfort.

This report examines four common frame materials used with aluminum screen mesh: aluminum, uPVC, timber, and steel. For each, we outline compatibility, advantages, limitations, and ideal applications to help you make informed decisions for your next project.

Aluminum frames are the most natural and technically compatible choice when using aluminum screen mesh.

· Thermal Compatibility: Both the frame and mesh expand and contract at similar rates under temperature fluctuations, minimizing stress and preventing loosening over time.

· Corrosion Resistance: With proper surface treatment (anodizing or powder coating), aluminum frames resist rust and degradation in harsh environments.

· Uniform Appearance: Offers a clean, modern aesthetic ideal for contemporary architecture.

· Lightweight yet strong, making it suitable for large installations.

· Requires minimal maintenance—no painting or sealing needed.

· Highly durable in coastal and humid climates.

· Fully recyclable, supporting sustainable building practices.

· Coastal residential and commercial buildings exposed to salt spray.

· High-rise apartment balconies and patio enclosures.

· Architectural facades and sunscreens where appearance and longevity matter.

· Higher initial cost compared to uPVC or basic timber.

· Can dent under heavy impact if not reinforced with thicker gauges.

Tip: For heavy-duty applications, specify thicker wall profiles (e.g., 1.4 mm or more) and powder-coated finishes for enhanced durability.

uPVC is a popular choice in residential and light commercial construction due to its affordability and ease of use.

· uPVC does not corrode, rot, or attract pests, making it a stable base for aluminum mesh.

· The smooth surface allows for clean, seamless mesh retention and easy cleaning.

· Resistant to moisture, mold, and UV degradation—ideal for wet areas.

· Excellent thermal insulation properties, contributing to energy efficiency.

· Low maintenance: no painting, sealing, or rust treatment required.

· Cost-effective for large-volume residential developments.

· Standard residential windows and sliding doors.

· Interior screens for kitchens, bathrooms, and utility rooms.

· Greenhouses and pool enclosures in moderate climates.

· Limited structural strength—may not support very large or heavy mesh panels.

· Can become brittle in extreme cold or discolor under prolonged UV exposure.

· Less suitable for high-wind or high-impact zones.

Tip: Choose UV-stabilized uPVC grades for outdoor installations in sunny regions.

Timber remains a preferred choice where visual appeal and traditional design are priorities.

· The contrast between the natural grain of wood and the sleek metallic finish of aluminum mesh creates a visually appealing combination.

· Hardwood frames offer solid support for mesh tensioning systems.

· High compressive strength, especially with dense species like oak, teak, or meranti.

· Can be stained or painted to match architectural styles.

· Provides better thermal insulation than metal frames.

· Ideal for heritage or custom-designed buildings.

· Heritage restoration projects and traditional homes.

· Resorts, lodges, and boutique hotels with rustic or natural themes.

· Interior room dividers and screened porches.

· Requires regular maintenance: sealing, staining, and inspection for rot or insect damage.

· Susceptible to warping and swelling in humid or wet environments.

· Heavier than aluminum or uPVC, increasing labor and installation costs.

Tip: Use kiln-dried, rot-resistant hardwoods and apply protective finishes every 2–3 years for optimal performance.

Steel frames are used where structural performance and security are paramount.

· Steel provides a rigid, stable structure that can support large mesh panels under high wind or physical stress.

· Galvanized or powder-coated steel prevents rust and extends service life.

· Exceptional strength-to-size ratio, ideal for large openings.

· Suitable for high-security applications.

· Long lifespan when properly treated and maintained.

· Industrial facilities, warehouses, and power plants.

· Government buildings, prisons, and secure facilities.

· Large commercial entrances and high-traffic public areas.

· Prone to rust if coating is damaged or maintenance is neglected.

· Higher installation cost due to weight and handling requirements.

· Poor thermal performance—can create condensation or thermal bridging.

Tip: For outdoor use, specify hot-dip galvanized or stainless steel frames to prevent corrosion.

To make the best choice for your project, consider the following factors:

Factor | Considerations |

Climate and Exposure | Coastal areas favor aluminum or uPVC; humid zones require rot-resistant materials. |

Structural Requirements | Larger spans need stronger frames—aluminum or steel are preferred. |

Aesthetic Goals | Match the frame to the building’s style—modern, traditional, or industrial. |

Budget | Balance upfront cost with lifecycle expenses (maintenance, replacement). |

Maintenance Capacity | Projects with limited maintenance access should prioritize low-maintenance materials like aluminum or uPVC. |

Installation Conditions | Consider weight, handling, and on-site assembly requirements. |

The performance of an aluminum screen mesh system depends not only on the quality of the mesh but also on the suitability of the frame material. Each frame type—aluminum, uPVC, timber, or steel—offers unique benefits tailored to specific environments and project goals.

· Choose aluminum frames for the best technical match, durability, and low maintenance.

· Opt for uPVC when budget and ease of maintenance are top priorities.

· Select timber for aesthetic richness and traditional design compatibility.

· Use steel when maximum strength and security are required.

By aligning your frame selection with environmental conditions, functional needs, and long-term operational costs, you ensure a reliable, efficient, and visually cohesive screening solution.

Jiushen supplies premium aluminum screen mesh and provides technical support to help you pair it with the most suitable frame material for your project. Whether you're designing a coastal resort, a modern office complex, or a heritage renovation, we offer:

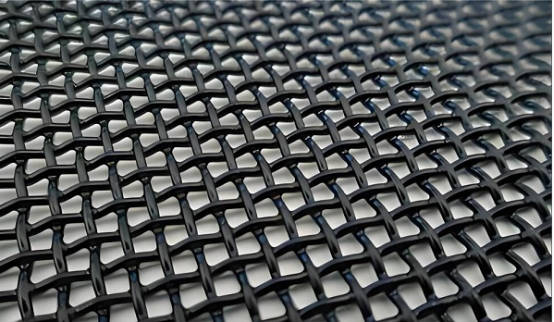

· High-quality, corrosion-resistant mesh in various weaves and finishes

· Custom cutting and roll sizing

· Technical consultation on system compatibility

· Sample kits for on-site testing

Contact us today to request a product sample or schedule a technical briefing.

Copyright © Hebei Jiushen Wire Weaving Co., Ltd. All Rights Reserved. |

Sitemap

| Technical Support: