Metal mesh, also referred to as woven wire mesh, is a calculated array of individual metallic wires interlocked together, forming pore openings with an exact size. Prior to the centuries-old weaving process used to fabricate the mesh, specifications, such as the mesh count, wire diameter, weave pattern, layer configuration, and alloy, are all predetermined.

Now, metal mesh can be molded and formed without compromising the integrity of the mesh openings. This allows it to deliver desirable filtration for a wide range of industries.

Filters are known to be porous materials designed to remove impurities and miscellaneous particles from liquids and gases. In the world of filtration, there are various materials used as filter media, such as metal fiber felt and wedge wire.

Mesh filers are a network of metallic wires that forms a pliable filter cloth with precise, rigid pore openings that engineers can customize to accommodate most filter systems. Additionally, because metal mesh filters are one of the most durable filter media available, they can be used in applications, such as sanitary pipe systems, to remove contaminants or in applications, such as nutsche filters, to extract a filter cake.

There are many benefits associated with metal mesh filters. This includes the filter's ability to be cleaned, accuracy, flow rate, and durability.

Let's look into how metal mesh can deliver the listed benefits.

As metal mesh features accurate pore openings, blinding and plugging are significantly reduced. This, combined with the enhanced flow rate, means system operators can clean the metal mesh easily.

These two properties allow the mesh filter to be backflushed and purged of any unwanted debris with minimal pressure.

The weaving process used to construct mesh filters is heavily monitored from start to finish. As a result, the pore openings of the filter are exact and uniform throughout the filter.

These precise pore opinings ensure that the end product, whether a filtered substance or a filter cake, is consistent and complies with industry standards.

One of the most significant advantages metal mesh has over most filter media used today is its ability to deliver an adequate flow rate. This is achievable as the wire diameter and mesh opening can be customized to perfectly match the contaminants you are filtering out, providing you with an enhanced level of filtration surface area.

This is especially true when a three-dimensional metal mesh filter is used. This is because three-dimensional mesh filters offset two layers of filter cloth, doubling the achievable flow rate.

While alloys such as Alloy 310, Super duplex, Duplex, Hastelloy C22, Inconel 600 and Titanium can be used to construct metal mesh filters, 300 series stainless steel is predominantly used. This helps create a filter that can withstand a wide range of impurities, pressure variations, and extreme temperatures without hindering the filter's accuracy.

In addition, stainless steel is a very pliable material, allowing the filter to be formed to fit your filter system and hold its shape after several uses.

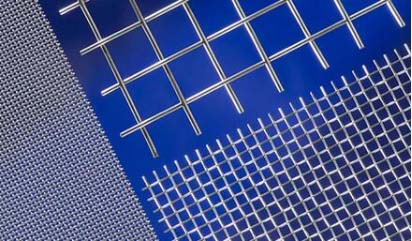

Multiple layers metal cloth filter with cut edge

The micron-leveled apertures are uniformly and precisely distributed, giving mesh filter greater accuracy, and can be used to filter the smallest particles in the world including a multitude of industries and applications like plastic & rubber reclamation.

Our metal woven cloth filter is woven by different weave types and materials to suit the market requirements. The common weave types include plain dutch & twill dutch. The former is designed for high flow and the latter for fine filtration. Apart from these two types, custom types are available such as reverse dutch weave & twill weave.

Stainless steel filter mesh is the most popular item for its good properties in resisting high temperatures, corrosions and deformation. Other materials are possible including galvanised steel, copper and other alloy steels.

● Item: woven wire mesh filter.

● Material: stainless steel 316, 304 and other alloy steels.

● Weave Type: twill dutch, plain dutch.

● Wire Edge: woven edge (for wire cloth in rolls or disc without rims).

● Elements: disc, circular ring, cylinder, basket, cone, oval, dome and bespoke shapes.

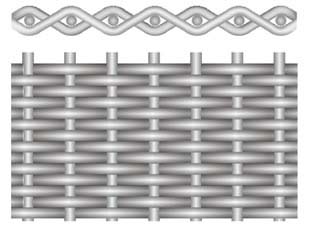

● Plain dutch weave

Plain dutch woven wire cloth used for high-flow filtration

Plain dutch woven wire cloth is woven by smaller wire in micron size in the shute direction with the larger wire in the wrap direction. Smaller shute wires provide tight mesh for filtering while larger warp wires provide strength and keep the mesh's shape. This kind of woven wire cloth is used in separating and filtering liquid and slurry product.

Characteristics: high flow rate, high temperature and no pressure drop.

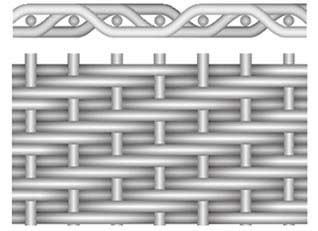

● Twill dutch weave

Twill dutch woven wire mesh used for fine filtration

Twill dutch woven wire Cloth with shute wires passing over and under two warp wires for gas & liquid filtration applications. Micron size wire provides the smallest apertures for monofilaments of fine filtration like hydraulic oil.

Characteristics: ideal for filtration among pharmaceutical and chemical industries as well as diverse types of filter systems such as cartridge and pre-coat.

| Plain Dutch Weave Wire Mesh | ||||

| No | Mesh/inch(WarpXWeft) | Diameter(Warp X Weft) | Aperture(μm) | Weight(kg/m2 ) |

| 32# | 8×62 | 0.63mm×0.45mm | 300 | 5.42 |

| 40# | 10×79 | 0.50mm×0.355mm | 250 | 3.16 |

| 48# | 12×64 | 0.58mm×0.40mm | 280 | 2.90 |

| 55# | 14×88 | 0.40mm×0.30mm | 180 | 2.54 |

| 76# | 19×140 | 0.315mm×0.20mm | 140 | 1.88 |

| 80# | 20×300 | 0.35mm×0.20mm | - | 3.6 |

| 95# | 24×110 | 0.355mm×0.25mm | 120 | 2.45 |

| 100# | 25×140 | 0.28mm×0.20mm | 100 | 1.95 |

| 120# | 30×150 | 0.25mm×0.18mm | 80 | 1.68 |

| 140# | 35×175 | 0.224mm×0.16mm | 71 | 1.52 |

| 160# | 40×200 | 0.20mm×0.14mm | 60 | 1.40 |

| 180# | 45×250 | 0.16mm×0.112mm | 56 | 1.09 |

| 200# | 50×250 | 0.14mm×0.112mm | 53 | 1.04 |

| 220# | 55.5×280 | 0.14mm×0.10mm | 50 | 0.92 |

| 240# | 65×330 | 0.11mm×0.08mm | 36 | 0.71 |

| 280#(1) | 70×350 | 0.11mm×0.08mm | 35 | 0.72 |

| 280#(2) | 70×385 | 0.11mm×0.07mm | 32 | 0.75 |

| 300# | 78×700 | 0.11mm×0.08mm | 30 | 1.39 |

| 315#(1) | 80×400 | 0.10mm×0.065mm | 40 | 0.62 |

| 315#(2) | 80×600 | 0.10mm×0.06mm | - | - |

| 315#(3) | 80×800 | 0.10mm×0.04mm | - | - |

| 320# | 81×780 | 0.10mm×0.07mm | 30 | 1.22 |

| 354# | 90×550 | 0.12mm×0..05mm | - | - |

| Roll width 1m-6m | ||||

| Twill Dutch Weave Wire Mesh | ||||

| No | Mesh/inch(WarpXWeft) | Diameter(Warp Xweft) | μmAperture | Kg/m2 |

| 360# | 91×787 | 0.10mm×0.07mm | 25 | 1.24 |

| 400# | 101×900 | 0.10mm×0.063mm | 20 | 1.22 |

| 472# | 120×400 | 0.10mm×0.075mm | - | - |

| 500# | 127×1100 | 0.07mm×0.05mm | 17 | 0.81 |

| 630# | 160×1500 | 0.063mm×0.04mm | 15 | 0.62 |

| 650#(1) | 165×400 | 0.07mm×0.06mm | - | - |

| 650#(2) | 165×600 | 0.07mm×0.05mm | - | - |

| 650#(3) | 165×800 | 0.07mm×0.05mm | 25 | - |

| 650#(4) | 165×1100 | 0.07mm×0.045mm | - | - |

| 650#(5) | 165×1400 | 0.07mm×0.04mm | 16 | 0.76 |

| 685# | 174×1700 | 0.063mm×0.032mm | 13 | 0.61 |

| 787#(1) | 200×600 | 0.07mm×0.06mm | - | - |

| 787#(2) | 200×800 | 0.07mm×0.05mm | - | - |

| 787#(3) | 200×1400 | 0.07mm×0.04mm | 12 | 0.8 |

| 795# | 202×1760 | 0.05mm×0.032mm | 10 | 0.6 |

| 850# | 216×1860 | 0.045mm×0.030mm | 9 | 0.5 |

| 1000# | 254×2000 | 0.04mm×0.028mm | 8 | - |

| 1125# | 285×2235 | 0.036mm×0.025mm | 7 | - |

| 1228# | 312×2100 | 0.035mm×0.025mm | - | - |

| 1250# | 318×2235 | 0.035mm×0.025mm | - | - |

| 1280# | 325×2300 | 0.035mm×0.025mm | 5 | 0.45 |

| 1575# | 400×3100 | 0.035mm×0.019mm | 3 | - |

| Roll width 1m-1.6m | ||||

● Precise aperture for filtration.

● Extremely high temperature.

● Excellent corrosion resistance.

● Washable, reusable & durable.

● Any bespoke shape available.

● Food & Beverage.

● Printing.

● Paper Making.

● Petroleum & Chemical Industry.

● Plastic & Rubber Reclamation.

● Oil & Gas Filtration.

● Hydraulic Filtration.

Custom Wire Mesh Filter is supplied for your special requirements like special material, weave types, dimensions and shapes. Bespoke mesh filter is one of our advantages in servicing our clients. Just email us your inquiry, prompt reply will be received.

Copyright © Hebei Jiushen Wire Weaving Co., Ltd. All Rights Reserved. |

Sitemap

| Technical Support: