When it comes to choosing materials for window screening and frames, the decision between aluminum and plastic is crucial. While plastic serves various purposes and applications, aluminum stands out as an excellent addition to any space.

Aluminum offers numerous advantages. It is a lightweight metal known for its corrosion resistance. When exposed to an oxidizing environment, aluminum naturally forms a protective coating, enhancing its durability against corrosion. Additionally, aluminum is odorless, ensuring that your new screens and frames won't overwhelm a room with any unwanted scents.

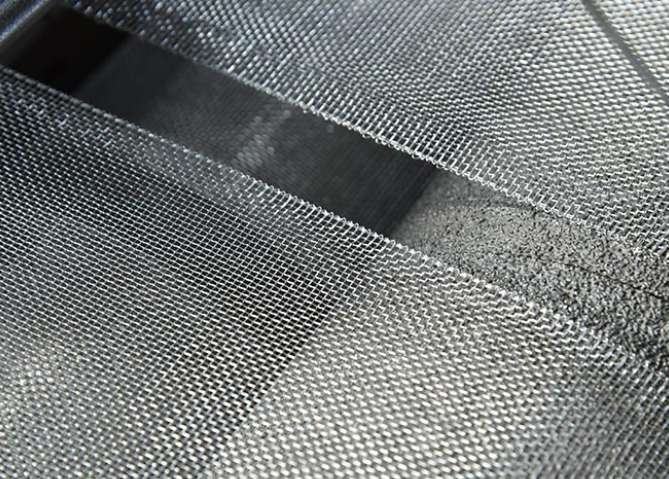

When choosing the material you want for your screens, it is important to know what each type offers. Screens made from aluminum mesh have limited color options, but they are one of the sturdiest and most durable screens available. They have a long lifespan and will offer you protection from different weather conditions, including rain, strong winds, and even hail in some cases. Constructed from aluminum, aluminum mesh screens offer exceptional resistance to abrasion, corrosion, and rust, making them an ideal choice for almost any environment. These fly screens made from aluminum wire maintain their shape without sagging or succumbing to rust, ensuring an extended lifespan. Opting for charcoal or black aluminum screens further enhances visibility by absorbing light and minimizing glare, thereby improving outward visibility.

In areas where extreme weather isn't a concern, plastic insect screens offer an affordable alternative to aluminum window screens. These screens effectively ward off mosquitoes, flies, and other insects while allowing fresh air into your home. Similar to aluminum screenings, plastic screening are lightweight but come with an added advantage of a UV-resistant coating, enhancing their durability.

Plastic has gained popularity in constructing privacy screens. These screens feature a heavy mesh combined with a protective plastic laminate, making them resilient against various weather conditions. They serve well in pool enclosures or patios, often placed in the lower section of pool enclosures to prevent grass clippings or provide privacy.

Both plastic and aluminum play significant roles in constructing screen frames and corners. While both materials boast durability, aluminum typically outlasts plastic. Your choice should be based on the location of your window and the prevailing weather conditions it will endure.

Aluminum alloy stands out as a 100% recyclable material that retains its original properties through recycling processes. Replacing screens and frames with aluminum doesn't negatively impact the environment. Moreover, the use of recycled aluminum during production helps keep prices competitive compared to extracting fresh metal from the ground. While certain plastics can harm the environment, those used in plastic insect screens are often recyclable or crafted from recycled materials, offering a safer alternative to other options.

Despite the cost efficiency stemming from aluminum's recyclability, it remains on the higher end in comparison to other window screening materials. This cost disparity is where plastic gains an edge over aluminum. The affordability of plastic makes it a more enticing choice for extensive projects that involve multiple levels in a home or business.

Determining the ideal material depends on the specific requirements of each job. Understanding the advantages of each material empowers you to make an informed decision. For further inquiries regarding our selection of window screening materials or any other products, please don't hesitate to reach out to us.

Copyright © Hebei Jiushen Wire Weaving Co., Ltd. All Rights Reserved. |

Sitemap

| Technical Support: